STL develops 160-micron fibre, the world's slimmest fibre and cable technology

Oct 28, 2023

PRNewswire

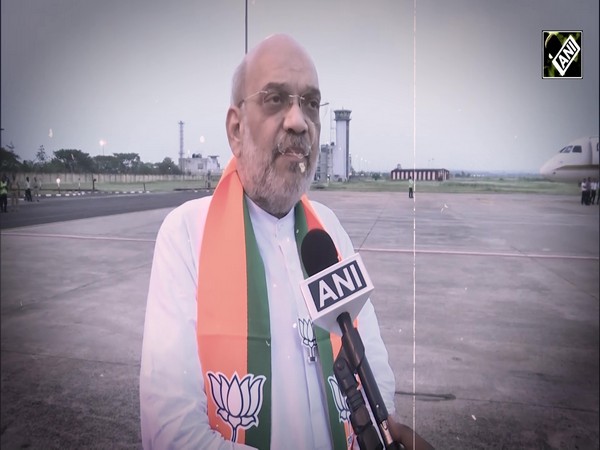

New Delhi [India]/ London [UK]/ Columbia (South Carolina) [US], October 28: In a proud achievement for India's R&D capability, STL [NSE: STLTECH], a leading optical and digital solutions company, today announced that it has developed the world's slimmest fibre for telecommunications - 160-micron Optical Fibre. Commending the technology innovations which are Designed in India and Made in India, Ashwini Vaishnaw, Union Minister for Communications, Electronics & Information Technology & Railways, unveiled this world-leading product at STL's booth in IMC 2023. Post unveiling the 160-micron Fibre, the H'onable minister 'spliced' or 'joined' two strands of optical fibre - a highly calibrated process of perfectly connecting the cores of two hair-thin optical fibres.

Cable made with STL's 160-micron fibre can pack 3X more capacity than traditional 250-micron fibre. This has been conceptualised and developed indigenously at STL's Centre of Excellence in Maharashtra, making STL among the first companies globally to develop and patent this industry-leading technology.

As India becomes the fastest-growing digital economy in the world, there's a need for densely fiberised networks, both in backhaul and closer to customers. Laying ducts account for ~60% of the entire fibre deployment cost, making duct space a precious asset. Network builders all over the globe are in a continued quest to reduce fibre size to pack in more and more capacity in the available duct space.

By packing more capacity in limited duct space with a reduced diameter cable of 6.4mm (~32% reduction compared to 250-micron fibre), STL's 160-micron fibre will revolutionise deployment, bandwidth capacity and green quotient of the networks. The at-scale impact of this innovation on India's broadband landscape can be immense. For example - In a large-scale project like Bharatnet, where India needs to deploy ~20 Million fibre km cable by 2025, using 160-micron fibre instead of the standard 250-micron fibre can potentially reduce the deployment time by ~15%. This enables the use of ducts with a smaller diameter, thereby reducing the plastic footprint in the ground by ~30%.

"This slimmest fibre is a noteworthy development and depicts our commitment to innovation and continuous R&D efforts in photonics and materials science," said Dr Badri Gomatam, Group CTO, STL.

Incremental reduction in fibre size is an incredibly challenging feat which has captured the imagination of optical experts across the world. Some of the key challenges in reducing fibre size below 250-micron include enhanced sensitivity towards micro-bending and increased complexity in the fibre drawing process.

Talking about solving these challenges, Dr Badri added, "Through highly calibrated process and material engineering, we have achieved a breakthrough in manufacturing processes and glass compositions to realise micro bend insensitivity. "

This product meets telecom-grade optical performance standards and complies with the ITU G.657A2 standard. This announcement comes after a series of innovations by our R&D experts, including India's first multicore fibre with 4X capacity and 180-micron fibre.

"This groundbreaking innovation exemplifies our passion to put Indian technology and R&D on the world map. I am extremely excited to imagine the future of India's digital networks with this disruptive fibre design," said Ankit Agarwal, Managing Director, STL.

About STL - Sterlite Technologies Ltd:

STL is a leading global optical and digital solutions company providing advanced offerings to build 5G, Rural, FTTx, Enterprise and Data Centre networks. Read more, Contact us, stl.tech | Twitter | LinkedIn| YouTube

Photo - https://mma.prnewswire.com/media/2259888/Shri_Ashwini_Vaishnav_at_STLs_booth_at_IMC_2023.jpg

Photo - https://mma.prnewswire.com/media/2259887/Shri_Ashwini_Vaishnav_unveils_160_micron.jpg

Logo - https://mma.prnewswire.com/media/876464/Sterlite_Technologies_STL_New_Logo.jpg

(ADVERTORIAL DISCLAIMER: The above press release has been provided by PRNewswire. ANI will not be responsible in any way for the content of the same)